Day 1 :

Keynote Forum

Lew P Christopher

Lakehead University, Canada

Keynote: Growing a high-value bioeconomy through biofuels and bioenergy production from low-value biomass waste

Time : 10:00-10:35

Biography:

Abstract:

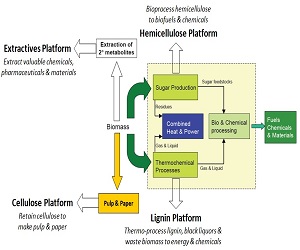

Biorefineries are our future oil refineries where oil is inevitably replaced by lignocellulosic biomass; the most abundant and renewable resource on earth that is reproduced at 60 billion tons a year. Biorefineries are viewed as one of the major economic pillars of the emerging global bioeconomy that can advance and accelerate our transition to a bio-based society. Major drivers of the transitioning process include increasing demand for food and energy, diminished oil reserves and unstable oil prices, and increasing concerns over global climate change and greenhouse gas emissions. Currently, however, less than 10% of the total global fuels and chemicals production is derived from biomass. This is mainly due to the fact that biofuels and biochemicals are not yet cost-competitive to their petroleum-based counterparts. The current cost of lignocellulose conversion to bioenergy (US $15-$25/GJ) exceeds the cost of fossil fuels (US $3.31-$17.37/GJ). Therefore, development of an economically-viable production system would require the use of low-value biomass and waste streams that are currently generated. As the feedstock costs comprise about 50% on average of the total production costs, it has now been recognized that biomass waste can provide a cost-effective alternative to improve the economic viability of the biorefineries. Utilization of low-cost or negative-cost biomass waste has at least two major advantages over any other lignocellulosic feedstock: Opportunity to significantly lower the overall production costs of targeted bioproducts (biofuels, biochemicals or biomaterials) and opportunity to significantly reduce waste treatment costs and carbon footprint. This presentation will discuss opportunities for valorization of waste streams and underutilized byproducts generated during processing of lignocellulosic biomass. Waste streams under consideration conclude municipal solid waste, agricultural residues, bark, sawdust, primary and secondary sludge, industrial hydrolysates, etc. Potential value-added bioproducts and related technological challenges will be critically reviewed.

Networking & Refreshment Break 10:35 - 10:55 @ Foyer

Keynote Forum

Chung-Huang Huang

Taiwan Research Institute, Taiwan

Keynote: Optimal policy integration for biofuels development and carbon reduction

Time : 10:55-11:30

Biography:

Abstract:

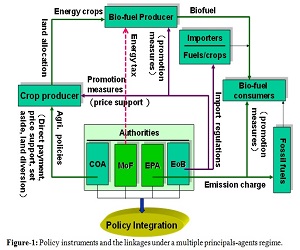

In response to the pressure of greenhouse gas (GHG) emission reduction, the authorities in Taiwan have been initiating a number of plausible policy instruments such as set-aside program by the Council of Agriculture (COA), Renewable Energy Development Act by the Bureau of Energy (BoE), carbon fee by the Environmental Protection Administration (EPA) and energy tax by the Ministry of Finance (MoF). National development targets of such renewables as wind power, biomass, solar energy, etc., are also promulgated by BoE under the Ministry of Economic Affairs. Quite often the policy instruments could hardly harmonize with each other due to weak coordination among authorities and incomplete enforcement. Socially desirable policy integration is, therefore, urgently needed so as to achieve the development targets cost-effectively and to mitigate the impacts on the economy. Despite the supply side of biofuels, including production techniques and policy instruments, had been pervasively presented, the demand-side management is much less addressed. Transportation sector, as an example, attracts much attention because not only its GHG emission continues to grow, but also it is the major sector consuming biofuels. It appears, however, that the policy instruments applicable to the Ministry of Transportation in Taiwan is limited and weakly linked to the prevailing policy framework. This leads to a policy failure in promoting the use of biodiesel in transportation sector such that truck drivers refuse to use biodiesel and retail sellers refuse to buy in biodiesel from producers. This paper examines the farmer’s willingness to accept for the production switched from traditional crops (e.g., rice) to energy crops. The properties of equilibria in crop markets are also discussed on the basis of a general equilibrium model that involves intertemporal decisions of multiple principals and agents. Furthermore, the optimal integration of alternative policy instruments is proposed, in the hope that the overall efficiency of policy mix could be enhanced. Specific emphasis will be placed on the derivation of the consumer’s willingness to pay for biofuels in the transportation sector. Accordingly, the demand for transportation services will be integrated into a general equilibrium framework, represented, to address the optimal policy mix with multiple principals and agents. It is expected that the findings could deliver constructive policy recommendations to the authorities and make profound contribution to the literature.

- Biofuels Production

Location: Raposo Tavares

Chair

Aharon Gedanken

Bar-Ilan University

Session Introduction

Aharon Gedanken

Bar-Ilan University, Isarel

Title: Using novel methods (Microwave Radiation and Sonochemistry) for the conversion of biomass to biofuels

Time : 11:30-11:55

Biography:

Abstract:

Rodrigo Morales-Vera

University of Washington, USA

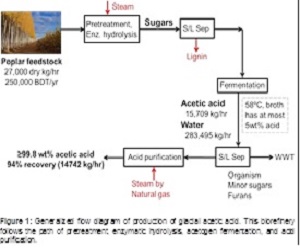

Title: Glacial acetic acid production from bioconversion of poplar biomass: Techno-economic assessment and environmental impacts

Time : 11:55-12:20

Biography:

Abstract:

Leonardo Curatti

National University at Mar del Plata, Argentina

Title: Algae-based multitrophic biomass biorefinery for the production of biofuels

Time : 12:20-12:45

Biography:

Abstract:

Statement of the Problem: Due to increased productivities and cultivation in marginal lands, microalgae have great potential as feedstock for biofuels alternative to plant crops. However, the current cost of producing biofuels from microalgae biomass is still high to envision massive and profitable commercialization in the near future. It is presumed that obtaining other higher-value byproducts in biorefineries would increase the profitability. Among other aspects, access to renewables as well as recycling of nutrients as substitutes for conventional fertilizers would be mandatory.

Methodology & Theoretical Orientation: We have been proposing alternative multispecies microbial cells-factories for the production of biofuels. Basically, the concept proposes the integration of operations that are exceptionally well performed by single microorganisms (whether naturally occurring or after genetic optimization) into multispecies systems than can execute more complex tasks and/or outperform any single species. We attempt to increase the use of N2 from the air as a sole source of N-fertilizer for microalgae.

Findings: We used a N2-fixing cyanobacterium that produces N-rich biomass that could be efficiently converted into biomass of a variety of microalgae. When using oleaginous strains, on-farm oil-production potential yields by ePBR simulations were up to 20-fold higher than those reported for soy oil. On the other hand, when we used microalgae accumulating carbohydrates (60-70% w/w), after a mild acid treatment for biomass hydrolysis and saccharification, bioethanol was produced at nearly 90% of its theoretical yield by fermentation with yeasts. The system also produced protein-rich biomass fractions as potential feed supplement and allowed some recycling of nutrients.

Conclusion & Significance: We have provided strong proof-of-principle suggesting potential for the economic and environmentally sustainable production of biofuels in multispecies biorefineries. Both on-farm demonstration and detailed modeling of environmental performance are required to take these ideas to a next step.

Panel Discussion and Key networking 12:45-13:00

Lunch Break 13:00-14:00 @ Foyer

Carole Molina-Jouve

Institute National des Sciences Appliquées, France

Title: Current status for prospects on advanced biofuel production: How to get through scientific and technological challenges as part of bioeconomy success?

Time : 14:00-14:25

Biography:

Abstract:

Quan Sophia He

Dalhousie University, Canada

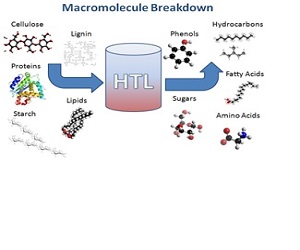

Title: Development of biofuels from biowastes via an emerging technology: Hydrothermal liquefaction

Time : 14:25-14:50

Biography:

Abstract:

Ivo Fouto

Cenerbio, Brazil

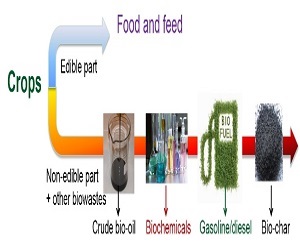

Title: Innovative energy crops dedicated for pulp & paper; bioenergy & biorefinery - Case study for Pyoil co-processing

Time : 14:50-15:15

Biography:

Abstract:

Wennan Zhang

Mid Sweden University, Sweden

Title: Review of algae hydrothermal liquefaction

Time : 15:15-15:40

Biography:

Abstract:

Cheng-Hung Chen

Taiwan Research Institute, Taiwan

Title: Evaluating the benefits for the policy instruments of green energy technology

Time : 15:40-16:05