Day 2 :

Keynote Forum

Ajit Sapre

Reliance Industries Limited, India

Keynote: Advances in renewable energy at Reliance Industries

Time : 10:00-10:35

Biography:

Abstract:

Networking & Refreshment Break 10:35-10:55 @ Foyer

Keynote Forum

Govinda R Timilsina

World Bank-Washington DC, USA

Keynote: Evolution of global biofuel markets and policy landscape

Time : 10:55-11:30

Biography:

Abstract:

During the decade of 2000, production of biofuels surged. Production of ethanol increased by almost 3 folds over the period of six year between 2004 and 2010 from 31 billion liter in 2004 to 86 billion liter in 2010. Production of biodiesel during the same period increased even at higher rate, more than 8 times, from 2.3 billion liters in 2004 to 19 billion liter in 2010. However, contrary to many projections made before 2010, the production of biofuels got stagnated and even decreased since 2010. While the production bounced back in 2013 and has been increasing gradually, the recent rates at which production increases are much smaller as compared to those observed in a decade ago. The lost momentum of biofuels since 2010 have been caused by several factors including fuel vs. food controversy, indirect land-use change debate, drop in oil prices, false promise of second generation biofuels and so on. This presentation will present the evolution of global biofuel markets and the policy drives behind the evolution. It also highlights some of the key factors responsible for the lost momentum after year 2010.

- Different forms of bioenergy

Location: Raposo Tavares

Chair

Fatima Bento

University of Rio Grande do Sul, Brazil

Session Introduction

Fatima Menezes Bento

University of Rio Grande do Sul, Brazil

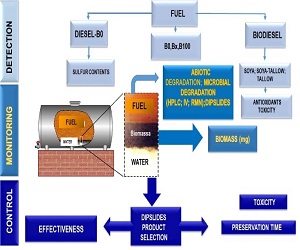

Title: Microbial contamination during storage time of diesel, biodiesel and blends (Bx): Detection, monitoring and control

Time : 11:30-11:55

Biography:

Abstract:

Statement of the Problem: Microbial contamination in fuels has been reported since 1895 and it is considered one of the main problems related to the maintenance of stored fuels’ quality. The impact of this contamination in the system depends mainly on the fuel grade, storage time and housekeeping schedules. Among the fuels, the diesel fuel formulation has changed a lot over time, mainly by the reduction of sulfur and addition of biodiesel. The purpose of this study is to describe the steps of detection, monitoring and control to avoid the installation of deteriogenic process during storage time by microbial contamination.

Methodology & Theoretical Orientation: Many studies were conducted to determine the microbial population (composition and growth capabilities) in diesel, blends Bx and biodiesel in lab conditions simulating the storage conditions. Biomass produced at interface oil-water in microcosms is a good indication of deteriogenic process in course, acidic conditions from the water phase; infrared and chromatographic analysis results to oily phase as well.

Findings: Our results have demonstrated that diesel/biodiesel blends are more susceptible to biodegradation and biomass formation during storage. The microbial composition was characterized and monitored by culture and non-culture methods (Illumina high throughput sequencing) and more than 800 genera were identified including Archea. We showed that fuel degradation, as evaluated by HATR-FTIR, was related to interfacial biofilm formation. After 60 days storage, the system treated with a multifunctional biocide package yielded more interfacial biomass, indicating that sub-effective doses may lead to increased microbial growth.

Conclusion & Significance: The determination of the level of microbial contamination is crucial to understand the vulnerability of fuel storage systems. Our results has revealed that microbial contamination is very diverse and that the use of biocide affects microbial community structure in the fuel but that some microorganisms are resistant to the biocide.

Suzana Marques Domingues

Bizup Business Leverage, Brazil

Title: Enhancing biogas generation from residues: A scale up challenge

Time : 11:55-12:20

Biography:

Abstract:

Henrique Baudel

America Biomass Technologies, Brazil

Title: Medium-scale biorefineries: A promising alternative for the sustainable production of biofuels, bioenergy and biochemicals at locally-based agro-industrial clusters

Time : 12:20-12:45

Biography:

Abstract:

Panel discussion and Key networking 12:45-13:00

Lunch Break 13:00-14:00 @ Foyer

Paulo Cesar Manduca

University of Campinas, Brazil

Title: Biofuels as inductor of bioeconomy: Comparative strategies in Brazil, Argentina and EU

Time : 14:00-14:25

Biography:

Abstract:

Luma Sh. Al-Saadi

Newcastle University, United Kingdom

Title: A comparative study of homogeneous base catalysts and process conditions for high biodiesel conversions from high free fatty acid rapeseed oil using a mesoscale oscillatory baffled reactor

Time : 14:25-14:50

Biography:

Abstract:

Eng. Silvio Ricardo Taboas

TabVlae Engineering Services ltda, Brazil

Title: A method and a system for converting large quantities of wastewater into water and fertilizer - The YSATÃŽ case, based on Patent INPI PI 0905596-7 A2

Time : 14:50-15:15

Biography:

Abstract:

Marcelo Maciel Pereira

Chemistry Institute of Federal University of Rio de Janeiro (UFRJ), Brazil

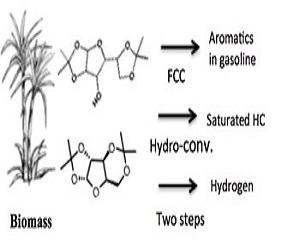

Title: Bio-hydrocarbon and bio-hydrogen in the standard refinery

Time : 15:15-15:40

Biography:

Abstract:

Regiane Alves de Oliveira

University of Campinas, Brazil

Title: First and second generation lactic acid production

Time : 15:40-16:05